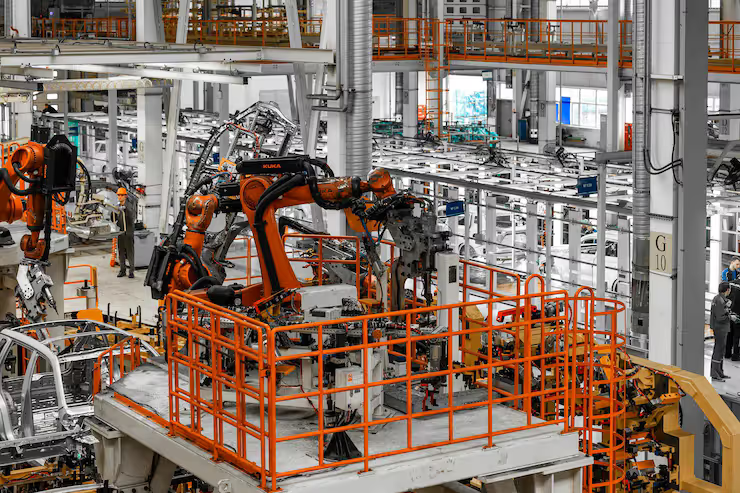

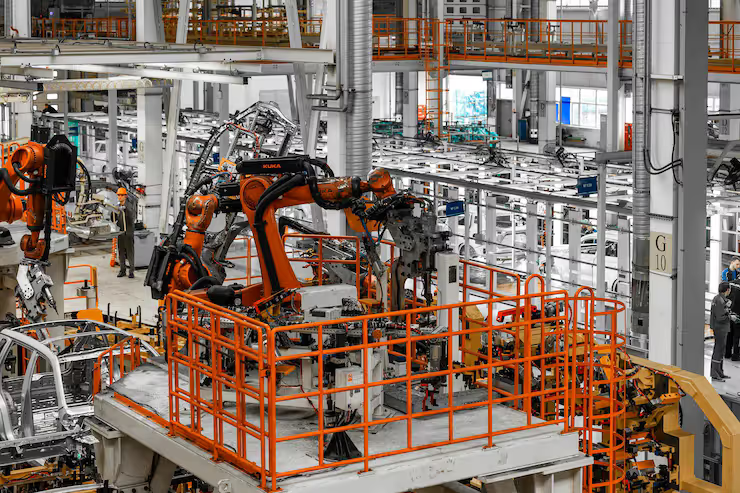

Industrial welding robots are automated robotic systems designed to perform welding tasks in manufacturing environments. These machines combine mechanical arms, sensors, controllers, and specialized software to create consistent welds with minimal manual intervention. They emerged as industries sought higher precision, safer working conditions, and scalable production efficiency.

Robotic welding automation is widely used in automotive manufacturing, heavy equipment fabrication, aerospace engineering, shipbuilding, and structural steel production. These sectors require repeatable weld quality, speed, and reduced human exposure to heat, fumes, and hazardous conditions.

Unlike manual welding, robotic welding systems operate through programmed instructions, vision sensors, and artificial intelligence-driven calibration. Advanced industrial robot programming allows adaptive welding, where machines adjust parameters based on material thickness, joint position, or environmental variables.

Key facts about industrial welding robots include:

-

Arc welding robots dominate manufacturing automation globally

-

Sensor-guided robotic welding improves accuracy in complex assemblies

-

Integration with smart manufacturing robotics enhances data monitoring

-

AI welding automation supports predictive maintenance and quality control

These capabilities make robotic welding a cornerstone technology in modern Industry 4.0 ecosystems.

Importance and Industry Impact

Industrial welding robots have become central to manufacturing productivity and quality assurance. Their adoption influences several industrial sectors, especially those requiring precision fabrication and consistent output.

The importance of automated welding technology includes:

-

Improved weld consistency compared with manual welding

-

Reduced workplace exposure to welding hazards

-

Higher production efficiency in large-scale fabrication

-

Integration with digital manufacturing analytics

Industries benefiting most include automotive assembly plants, aerospace component manufacturing, metal infrastructure projects, and energy equipment fabrication.

Major Problems Addressed by Robotic Welding Automation

| Challenge | Robotic Solution |

|---|---|

| Human exposure to heat and fumes | Automated welding arms reduce direct exposure |

| Inconsistent weld quality | Programmed precision ensures uniform welds |

| Production delays | Continuous robotic cycles improve throughput |

| Complex weld geometries | Multi-axis robotic movement enhances flexibility |

Automation also supports industrial sustainability goals. Precise welding reduces material waste, lowers rework rates, and improves energy efficiency in fabrication processes.

From a workforce perspective, robotic welding shifts human roles toward system supervision, robotic programming, safety monitoring, and quality analysis rather than direct manual welding tasks.

Recent Updates and Emerging Trends

Industrial welding robotics continues evolving rapidly due to artificial intelligence, sensor innovation, and advanced industrial automation platforms. Over the past year, several developments have shaped the field.

AI-Driven Welding Optimization (2025)

Manufacturers increasingly deploy machine learning algorithms to optimize welding parameters automatically. These systems analyze historical weld data to improve consistency and reduce defects.

Collaborative Welding Robots Expansion (2024–2025)

Collaborative robots, often called cobots, allow safer interaction between humans and robotic systems. Improved force sensors and real-time monitoring enable closer operator supervision without compromising safety.

Digital Twin Technology Adoption (2025)

Digital twin simulations replicate welding environments virtually. Engineers use these simulations to test robotic welding automation strategies before deployment, improving efficiency and reducing operational disruptions.

Smart Manufacturing Integration (2024)

Robotic welding systems increasingly integrate with industrial IoT platforms, enabling:

-

Real-time performance analytics

-

Predictive maintenance alerts

-

Remote monitoring dashboards

-

Data-driven production optimization

Emerging Trend Snapshot

| Trend | Impact on Industry |

|---|---|

| AI welding automation | Adaptive weld precision |

| IoT connectivity | Continuous performance tracking |

| Collaborative robots | Improved human-robot interaction |

| Digital twins | Enhanced planning accuracy |

These trends reflect a broader shift toward intelligent manufacturing ecosystems where robotics, analytics, and automation converge.

\Laws, Regulations, and Policy Considerations

Industrial welding robots operate under various workplace safety regulations, manufacturing standards, and industrial automation policies. These frameworks vary by country but generally focus on safety, equipment compliance, and environmental considerations.

In India, industrial automation guidelines often align with:

-

Occupational safety standards under the Factories Act

-

Bureau of Indian Standards (BIS) industrial equipment norms

-

Workplace safety directives related to hazardous operations

Globally, welding robot safety commonly references international frameworks such as ISO robotic safety standards and occupational safety directives. These regulations emphasize:

-

Machine guarding and emergency stop systems

-

Worker training for robotic interaction

-

Electrical safety compliance

-

Environmental emission controls

Government initiatives promoting smart manufacturing also influence adoption. Many countries support advanced manufacturing automation through innovation policies, technology adoption incentives, and workforce reskilling programs.

Compliance ensures safe deployment while supporting industrial modernization.

Tools and Helpful Resources

Professionals working with robotic welding automation benefit from specialized tools, simulation platforms, and knowledge resources.

Software and Technical Tools

-

Robotic welding simulation platforms for virtual programming

-

Industrial robot programming environments

-

Welding parameter optimization calculators

-

Predictive maintenance analytics dashboards

Educational and Industry Resources

-

Robotics engineering training platforms

-

Welding automation technical journals

-

Manufacturing automation webinars and conferences

-

Industrial safety compliance documentation portals

Operational Support Resources

| Resource Type | Purpose |

|---|---|

| Simulation software | Process testing before implementation |

| Sensor calibration tools | Precision adjustment |

| Data analytics dashboards | Performance monitoring |

| Training modules | Skill development |

These resources support safe implementation, operational efficiency, and ongoing system improvement.

Frequently Asked Questions

What is an industrial welding robot?

An industrial welding robot is an automated mechanical system programmed to perform welding tasks using sensors, robotic arms, and control software for precision fabrication.

Where are welding robots commonly used?

They are widely used in automotive manufacturing, aerospace fabrication, shipbuilding, heavy machinery production, and structural steel industries.

Do welding robots replace human welders?

They typically complement human expertise. Workers often focus on programming, supervision, inspection, and maintenance rather than direct welding.

What types of welding can robots perform?

Common robotic welding processes include arc welding, spot welding, laser welding, and plasma welding.

Are robotic welding systems safe?

When compliant with industrial safety standards and proper training protocols, they enhance workplace safety by reducing exposure to hazardous conditions.

Conclusion

Industrial welding robots represent a major advancement in manufacturing automation, combining precision engineering, artificial intelligence, and smart manufacturing connectivity. Their role continues expanding as industries prioritize consistent quality, operational efficiency, workplace safety, and digital transformation.

Recent developments such as AI welding automation, collaborative robotics, and digital twin modeling demonstrate how automation technologies are evolving beyond simple mechanical tasks into intelligent, adaptive systems.

Understanding regulatory requirements, technological trends, and operational tools helps organizations implement robotic welding effectively while maintaining compliance and efficiency. As manufacturing continues transitioning toward Industry 4.0, industrial welding robots will remain essential components of advanced production ecosystems.