Wrapping machines are automated tools used to wrap products for protection, preservation, and transportation. These machines are essential in packaging lines across various industries, including food and beverages, pharmaceuticals, logistics, manufacturing, and consumer goods.

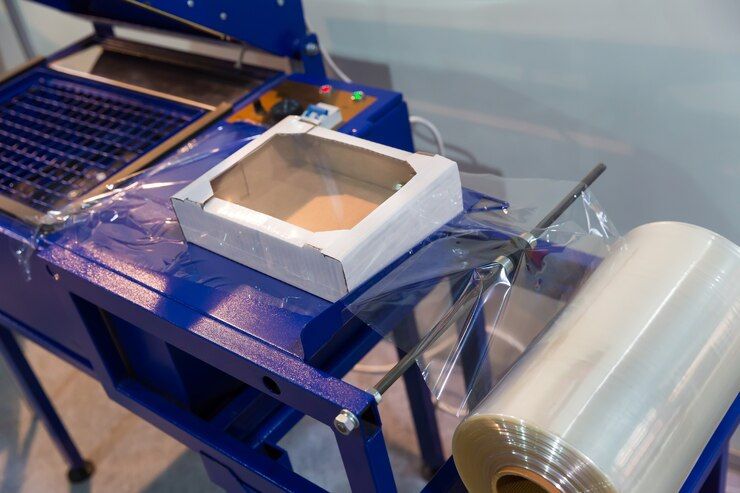

They come in different types like stretch wrappers, shrink wrappers, and flow wrappers, each designed for specific materials and end-use cases. Wrapping ensures items are sealed securely, protecting them from dust, moisture, and damage during handling or shipping.

The purpose behind using wrapping machines is to increase efficiency, reduce human error, and improve packaging consistency.

Why Wrapping Machines Matter in Modern Industry

Wrapping machines have become an essential part of industrial automation and logistics for several reasons:

-

Efficiency and Speed: Automating wrapping reduces manual labor and speeds up packaging lines.

-

Product Safety: Wrapping protects against contamination, damage, and environmental exposure.

-

Cost Reduction: Shrink and stretch film are cost-effective materials that offer secure packaging with minimal waste.

-

Sustainability: Modern machines reduce film usage and support recyclable materials.

-

Branding and Compliance: Proper wrapping ensures goods meet labeling and safety standards.

These machines impact manufacturers, distributors, retailers, and logistics providers by streamlining operations and ensuring goods reach consumers intact.

Recent Updates and Trends in Wrapping Machines (2024–2025)

Over the past year, the wrapping machine industry has seen innovations focused on sustainability, automation, and integration with smart technologies:

-

Smart Wrappers: Machines now come with IoT-enabled sensors for real-time data on wrap quality and efficiency.

-

Eco-Friendly Films: Rise in demand for biodegradable and recyclable stretch films.

-

AI-Driven Operations: Some machines use AI for load detection, adjusting wrap tension automatically.

-

Compact Designs: New models are space-efficient for smaller facilities.

-

Increased Demand: According to a 2024 report by MarketsandMarkets, the global wrapping machine market is projected to grow at 6% CAGR, driven by the e-commerce boom and food packaging needs.

These updates are helping businesses reduce waste and improve throughput in response to environmental and consumer demands.

Legal Standards and Packaging Regulations

In many countries, packaging—including wrapping—must comply with safety, hygiene, and labeling laws. These include:

-

India: The Legal Metrology (Packaged Commodities) Rules require specific labeling and packaging declarations. FSSAI also governs food-grade packaging.

-

USA & EU: The FDA and EU Packaging and Packaging Waste Directive regulate packaging materials and recycling content.

-

Sustainability Mandates: Many governments have introduced Extended Producer Responsibility (EPR) programs, pushing businesses to use recyclable or biodegradable wrapping.

Failure to follow these regulations can result in penalties or product recalls, making compliance crucial for businesses.

Tools, Apps, and Resources for Efficient Wrapping

Several platforms and tools help businesses improve wrapping efficiency and compliance:

Useful Tools:

-

Stretch Film Calculator (Online): Helps calculate optimal film usage per pallet.

-

Packaging Automation Software (e.g., NiceLabel, Loftware): Integrates labeling with wrapping lines.

-

CMMS Software: Helps manage machine maintenance and reduce downtime.

Informative Websites:

-

Packaging World (packworld.com): Industry news, product updates, and innovations.

-

PMMI.org: Offers resources on packaging machinery standards and trends.

-

Make in India (Packaging Machinery): Government support schemes for Indian manufacturers.

Mobile Apps:

-

Scan & Wrap Systems: Mobile scanning apps that integrate barcode validation with wrapping automation.

Frequently Asked Questions

Q1. What types of wrapping machines are available?

Common types include stretch wrapping machines, shrink wrap machines, flow wrappers, and pallet wrappers. Each serves different applications based on product size and material.

Q2. Are wrapping machines eco-friendly?

Many modern machines use recyclable or biodegradable films and optimize material use, making them more sustainable compared to traditional manual wrapping.

Q3. How do wrapping machines impact product safety?

They ensure tight and secure packaging, reducing the risk of contamination, damage, or tampering during transport and storage.

Q4. What maintenance is required for wrapping machines?

Routine maintenance includes checking film tension, cleaning sensors, and lubricating mechanical parts. Using CMMS tools can streamline this process.

Q5. Can small businesses use wrapping machines?

Yes. Compact, semi-automatic models are available for SMEs, offering cost-effective packaging solutions without needing large-scale infrastructure.

Final Thoughts

Wrapping machines play a key role in the modern supply chain by combining speed, protection, and consistency in packaging. With rising demands in logistics and sustainability, they are no longer just tools—they're strategic investments for long-term efficiency and compliance.

Whether you’re in food processing, e-commerce, or industrial manufacturing, understanding and optimizing your wrapping systems can lead to significant improvements in operations, cost savings, and customer satisfaction.