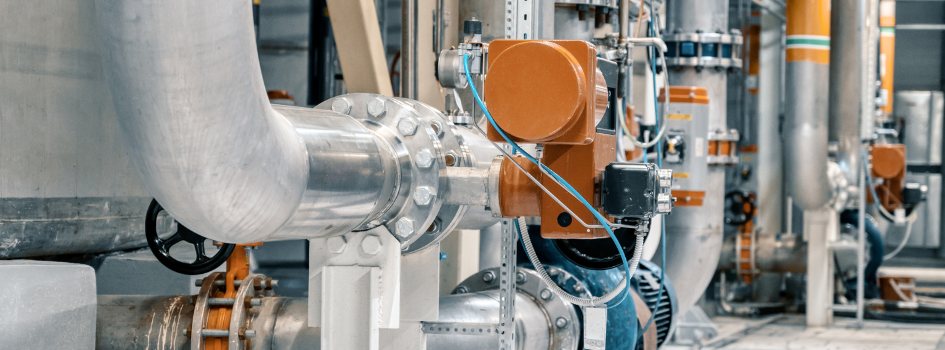

A chemical dosing system is a mechanical setup used to automatically introduce precise amounts of chemicals into a fluid stream. These systems are widely used in water treatment plants, industrial manufacturing, agriculture, and HVAC systems to ensure consistent chemical levels for safety, disinfection, or process control.

The purpose is to achieve accurate chemical delivery, minimize human error, and optimize efficiency in treating water, controlling pH, or dosing biocides, coagulants, or acids. These systems typically include tanks, dosing pumps, control panels, and safety sensors.

Why Chemical Dosing Systems Matter Today

Chemical dosing systems are vital to many sectors for the following reasons:

-

Water Safety: In municipal and industrial water treatment, they help maintain safe levels of chlorine, pH adjusters, or anti-scaling agents.

-

Process Efficiency: In chemical and manufacturing industries, consistent dosing ensures stable production quality and reduces waste.

-

Environmental Compliance: Proper dosing prevents overuse or discharge of harmful chemicals into the environment.

-

Workplace Safety: Automation reduces exposure risks to hazardous chemicals for workers.

-

Cost Reduction: Accurate dosing minimizes excess usage of costly chemicals, leading to operational savings.

Users include water utilities, food processing facilities, pharmaceutical companies, and agricultural irrigation systems.

Recent Trends and Updates in Chemical Dosing Technology

Over the past year (2024–2025), the chemical dosing sector has seen several important advancements:

-

Smart Control Systems: IoT-based dosing units now integrate with SCADA systems to provide real-time monitoring and remote control.

-

Energy-Efficient Pumps: Manufacturers are introducing low-power diaphragm and peristaltic pumps to reduce electricity consumption.

-

Modular Skid Systems: Pre-assembled skid systems allow for plug-and-play setup, saving installation time and space.

-

Chemical Detection Integration: Real-time analyzers monitor chemical concentration and adjust dosage automatically.

-

Green Dosing Chemicals: Increased use of environmentally safer dosing chemicals due to global regulations on hazardous substances.

Industries are shifting from manual or semi-auto systems to intelligent automation to enhance performance and reduce environmental impact.

Laws, Regulations, and Safety Compliance for Dosing Systems

Governments and international bodies have established strict norms regarding chemical handling and dosing systems:

-

ISO 9001 & ISO 14001 Standards: Define quality and environmental requirements for dosing system manufacturing and operation.

-

BIS (India) – IS 10500 & CPCB Norms: Regulate chemical dosing in drinking and wastewater treatment.

-

OSHA (USA): Enforces worker safety measures related to chemical exposure and automated dosing.

-

REACH (EU): Requires documentation and control over hazardous chemicals used in dosing processes.

-

EPA Guidelines (USA): Mandate limits on chemical discharges in industrial effluent and treated water.

Following these regulations ensures safety, legal compliance, and sustainability across public and private sectors.

Helpful Tools, Apps, and Resources

To support effective chemical dosing system design and monitoring, the following tools and resources are useful:

Design Calculators and Configurators

-

Grundfos Dosing Calculator – For calculating chemical feed rates and selecting appropriate pumps.

-

Lutz-Jesco Dosing System Designer – Web-based tool for complete system planning.

-

Seko Dosing Configurator – Helps select metering systems by chemical type and application.

Monitoring and Automation Tools

-

SCADA Integration Panels – For real-time monitoring and control.

-

pH and Chlorine Analyzers – Used in municipal and pool water treatment plants.

-

DCS Software Modules – In-built dosing logic in Distributed Control Systems.

Reference and Compliance Materials

-

WHO Water Treatment Guidelines – Covers chemical dosing best practices for potable water.

-

EPA Chemical Safety Checklist – A guide for safe handling and storage of dosing agents.

Frequently Asked Questions (FAQs)

Q1. What chemicals are commonly used in dosing systems?

Chlorine, alum, ferric chloride, sulfuric acid, caustic soda, and polyphosphates are commonly dosed in water treatment and industrial systems.

Q2. How does a dosing pump work?

A dosing pump delivers a measured amount of chemical into a process line. It’s usually controlled by flow sensors or programmable logic to ensure accuracy.

Q3. Can chemical dosing systems be used in agriculture?

Yes, they are widely used in fertigation (fertilizer + irrigation) systems to add nutrients and pesticides into irrigation pipelines.

Q4. What safety precautions are necessary when operating these systems?

Use personal protective equipment (PPE), follow SDS (Safety Data Sheet) instructions, install leak sensors, and train personnel on emergency handling.

Q5. Are there eco-friendly alternatives in chemical dosing?

Yes, many suppliers now offer green chemical agents and low-waste dosing techniques to reduce environmental impact.

Final Thoughts

Chemical dosing systems are critical in maintaining the safety, efficiency, and quality of processes across various sectors. From water treatment plants to agricultural fields, these systems enable precision and control in chemical application.

As regulations tighten and automation becomes more accessible, industries are adopting smart, sustainable dosing technologies to balance productivity with responsibility. Selecting the right system and following compliance standards ensures long-term performance and safety.