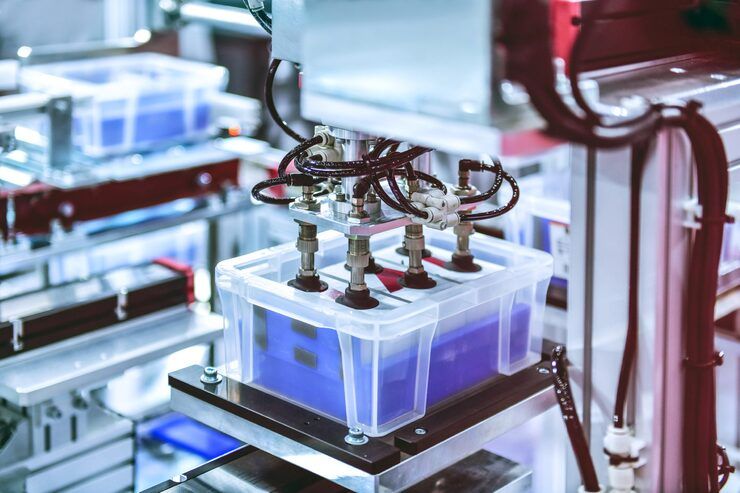

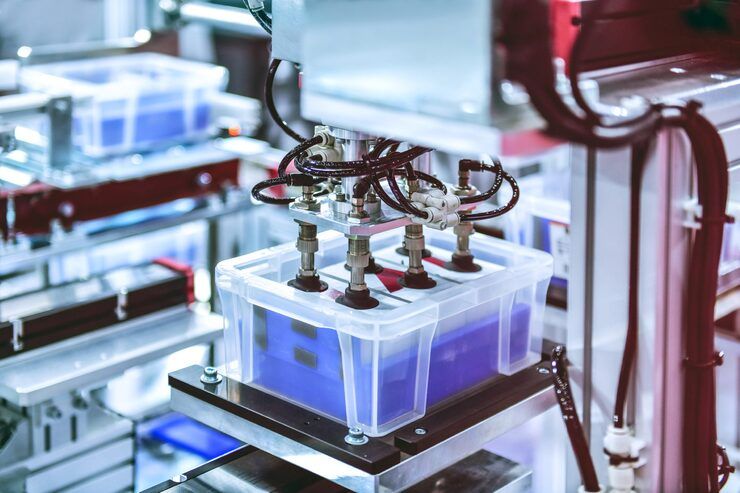

Battery manufacturing machines are specialized industrial systems used to produce battery cells and packs through automated processes such as material preparation, electrode formation, assembly, and testing. These machines exist to ensure precision, safety, and consistent quality while supporting large-scale production required by modern energy storage and electrification industries.

As demand for rechargeable batteries expanded across electric vehicles, renewable energy storage, and consumer electronics, automated battery manufacturing equipment became essential for high-speed and reliable industrial production.

Importance: Why Battery Manufacturing Machines Matter in Industry

Battery production requires strict control over material handling and assembly accuracy, making advanced machinery critical for modern manufacturing.

1. Precision Manufacturing

Automated machines ensure accurate electrode alignment and cell assembly for consistent battery performance.

2. Large-Scale Production Capability

Supports continuous manufacturing required for growing global energy storage demand.

3. Safety Enhancement

Reduces manual handling of sensitive chemical materials and improves workplace safety.

4. Product Quality Consistency

Maintains uniform battery capacity, durability, and reliability across production batches.

5. Industrial Automation Integration

Supports smart manufacturing and high-efficiency production environments.

Battery Manufacturing Process

1. Raw Material Preparation

Active materials and chemical compounds are prepared to form electrode mixtures.

2. Slurry Mixing Process

Materials are blended into uniform slurry formulations for electrode coating.

3. Electrode Coating

Slurry is applied onto metal foil surfaces to create battery electrodes.

4. Drying and Compression

Coated electrodes are dried and compressed to improve density and conductivity.

5. Cutting and Shaping

Electrodes are cut into precise sizes required for battery cell assembly.

6. Cell Assembly

Electrodes, separators, and components are arranged into battery cell structures.

7. Electrolyte Filling

Electrolyte solution is injected to enable electrochemical reactions.

8. Sealing and Formation

Cells are sealed and charged to activate stable battery performance.

9. Testing and Quality Inspection

Batteries undergo electrical and safety tests to ensure reliability.

10. Final Packaging

Completed batteries are assembled into packs and prepared for industrial distribution.

Main Battery Manufacturing Machines

1. Mixing Machines

Blend active materials uniformly to create stable electrode slurry for consistent battery performance.

2. Coating Machines

Apply electrode materials evenly onto foil surfaces to ensure balanced energy distribution.

3. Drying Ovens

Remove moisture from coated electrodes and stabilize material structure.

4. Calendering Machines

Compress electrodes to improve density and enhance energy efficiency.

5. Slitting and Cutting Machines

Cut electrode sheets precisely for accurate cell assembly.

6. Stacking or Winding Machines

Arrange electrode layers in compact structures to form battery cells.

7. Electrolyte Filling Machines

Inject electrolyte accurately to support chemical reactions inside cells.

8. Sealing Machines

Seal battery cells securely to prevent leakage and contamination.

9. Formation Equipment

Performs controlled charging cycles to stabilize battery performance.

10. Battery Testing Machines

Measure voltage, capacity, and safety performance before release.

Battery Manufacturing Equipment and Applications

| Equipment Type | Main Function | Industrial Application |

|---|---|---|

| Mixing Machine | Material blending | Battery production lines |

| Coating Machine | Electrode coating | Lithium battery manufacturing |

| Calender Machine | Electrode compression | Energy storage systems |

| Winding Machine | Cell assembly | Cylindrical battery production |

| Testing Equipment | Quality control | Industrial battery testing |

Industrial Applications of Battery Manufacturing Machines

1. Electric Vehicle Industry

Supports large-scale production of EV battery systems.

2. Consumer Electronics

Manufactures batteries used in smartphones, laptops, and portable devices.

3. Renewable Energy Storage

Produces batteries used for solar and wind energy storage systems.

4. Industrial Backup Power Systems

Supports uninterrupted power supply and energy storage solutions.

5. Medical Equipment Industry

Manufactures reliable batteries for portable healthcare devices.

6. Aerospace and Defense

Supports high-performance battery production for advanced applications.

7. Telecommunications Industry

Provides battery systems for network infrastructure and communication backup.

Benefits of Battery Manufacturing Machines

1. High Precision Production

Ensures uniform quality and stable battery performance.

2. Increased Manufacturing Efficiency

Supports high-speed automated production lines.

3. Improved Safety Standards

Minimizes risks during chemical and electrical processing.

4. Reduced Material Waste

Accurate processing improves resource utilization.

5. Scalable Production Systems

Allows expansion to meet growing industrial demand.

Challenges & Considerations

1. Complex Manufacturing Environment

Production requires controlled cleanroom conditions.

2. High Equipment Investment

Advanced machinery involves significant setup requirements.

3. Strict Quality Control Needs

Continuous inspection is required for safety compliance.

4. Technology Evolution

Frequent innovation demands adaptable equipment.

5. Energy Consumption Management

Certain processes require efficient energy control.

How to Choose the Right Battery Manufacturing Machines

1. Identify Battery Type

Select equipment compatible with lithium-ion, lead-acid, or other battery technologies.

2. Evaluate Production Capacity

Choose machinery according to output requirements.

3. Check Automation Level

Determine manual, semi-automatic, or fully automated production needs.

4. Review Precision and Quality Features

Ensure machines meet industry performance standards.

5. Assess Integration Capability

Machines should connect seamlessly within production lines.

Maintenance & Best Practices

1. Regular Calibration

Maintains machine accuracy and product consistency.

2. Cleanroom Maintenance

Prevents contamination affecting battery quality.

3. Mechanical Inspection

Checks moving parts to reduce breakdown risk.

4. Software and Control Updates

Ensures optimal machine performance.

5. Preventive Maintenance Scheduling

Reduces downtime and improves operational reliability.

Frequently Asked Questions

What are battery manufacturing machines used for?

They automate production of battery cells and energy storage systems.

Which industries use battery manufacturing equipment?

EV, electronics, renewable energy, and industrial sectors.

Are battery production lines automated?

Many modern factories use highly automated systems.

Why are cleanrooms required?

They prevent contamination that affects battery performance.

How long do battery manufacturing machines last?

Typically 10–20 years with proper maintenance.

Conclusion

Battery manufacturing machines are essential for producing high-quality energy storage solutions required by modern industries. Through precise automation, controlled processes, and advanced quality testing, these machines support large-scale battery production for electric mobility, renewable energy, and industrial applications.

Understanding the process, equipment, and industrial uses helps manufacturers choose suitable systems for efficient and reliable battery production. As electrification and sustainable energy technologies continue to grow, battery manufacturing equipment will remain a key driver of industrial innovation.