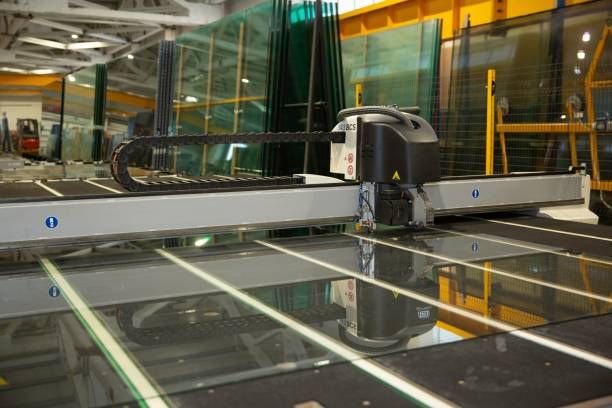

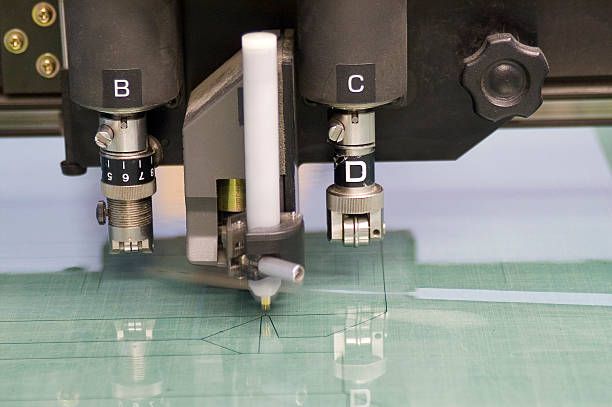

CNC (Computer Numerical Control) cutting is a precise and automated method used for shaping various materials. When applied to glass, CNC cutting machines use diamond-tipped tools, high-speed routers, or water jets to create detailed cuts, holes, and edges with exceptional accuracy.

Glass CNC cutting exists to support industries where precision is critical—architecture, automotive, electronics, home décor, solar panels, and more. Unlike manual methods, CNC ensures repeatability, reduces waste, and improves safety in cutting fragile glass surfaces.

Why Glass CNC Cutting Matters Today

CNC glass cutting plays a vital role in modern production due to these key reasons:

-

Precision in Manufacturing: Enables accurate cuts, especially for curved or intricate designs.

-

Increased Demand in Architecture: Used in curtain walls, glass partitions, facades, and staircases.

-

Essential in Electronics: Smartphone screens, touch panels, and sensor glass are all CNC-cut.

-

Energy Sector: Solar panel glass requires specific shape and thickness, achievable only with CNC tools.

-

Safety and Efficiency: Reduces the risk of cracks and human error in industrial-scale production.

This technology affects professionals in glass processing units, architects, engineers, OEMs, and interior designers who rely on consistent and reliable outputs.

Recent Developments in CNC Glass Cutting (2024–2025)

Recent advancements have improved the speed, safety, and flexibility of glass cutting machines:

-

2024 – Integrated AI Control Systems: Smart software now optimizes tool paths and reduces breakage.

-

Touchless Automation: Glass loading, aligning, and cutting are now fully automated in many industries.

-

CO₂ and Ultrafast Laser Cutting: New non-contact cutting methods are emerging for ultra-thin glass.

-

Eco-Friendly Waterjet Systems: Reduce dust and eliminate the need for cutting lubricants.

-

Global Expansion of Glass Processing Plants: Especially in India, UAE, and Southeast Asia to meet construction demand.

These innovations make CNC glass cutting more accessible and sustainable for small and large businesses alike.

Regulations and Standards for CNC Glass Cutting

Governments and industry associations enforce safety and manufacturing standards for CNC-based operations:

-

ISO 23125: Safety standards for CNC machines.

-

CE and BIS Certifications (India): Required for machines used in commercial production.

-

OSHA (USA): Mandates workplace safety protocols for glass handling and machine operation.

-

RoHS Compliance: Ensures machines and materials are free of harmful substances.

-

Local Building Codes: May require certified cutting for architectural glass installations.

Following regulations helps manufacturers ensure safe operation, quality assurance, and compliance with international supply chains.

Useful Tools, Calculators, and Resources

Whether you’re a fabricator, designer, or plant manager, these tools can support your work:

Design and Programming Tools

-

AutoCAD with CNC Plugin – For drawing patterns and exporting G-code.

-

NC Studio & Mach3 Software – Common CNC control platforms.

-

OptiNest – For optimizing material layout before cutting.

CNC Cutting Simulators and Calculators

-

Tool Path Generators (e.g., Fusion 360)

-

Feed Rate Calculators for Glass

-

Breakage Risk Calculators (used in high-precision projects)

Knowledge Platforms

-

Glass Magazine

-

CNCzone Forum

-

Intermac & Bottero CNC Guides

These resources provide valuable support for improving workflow, safety, and cost efficiency.

Frequently Asked Questions (FAQs)

Q1. What types of glass can be cut with CNC machines?

CNC systems can cut float glass, tempered glass, laminated glass, frosted glass, and low-E coated glass using appropriate tools and speeds.

Q2. What cutting tools are used in glass CNC machines?

Depending on the application, machines use diamond wheels, water jets, or laser cutters for different glass types and thicknesses.

Q3. How is CNC glass cutting different from laser cutting?

Laser cutting can cause thermal stress in thicker glass, whereas CNC waterjet or diamond cutting avoids heat damage and provides cleaner edges.

Q4. Is CNC glass cutting suitable for small businesses?

Yes. There are compact and affordable CNC machines designed for small-scale or custom glass fabrication.

Q5. What are common safety practices during glass CNC cutting?

Operators must use protective gear, dust collectors, and proper machine guards to prevent injuries and ensure clean cuts.

Final Thoughts

Glass CNC cutting is more than just a manufacturing method—it’s a critical technology shaping the future of construction, electronics, and interior design. With improved automation, AI-based controls, and eco-friendly approaches, CNC cutting continues to evolve for both large-scale production and custom applications.

Whether you’re investing in a CNC system or managing a production floor, understanding the machines, materials, and legal guidelines ensures better decisions and outcomes.